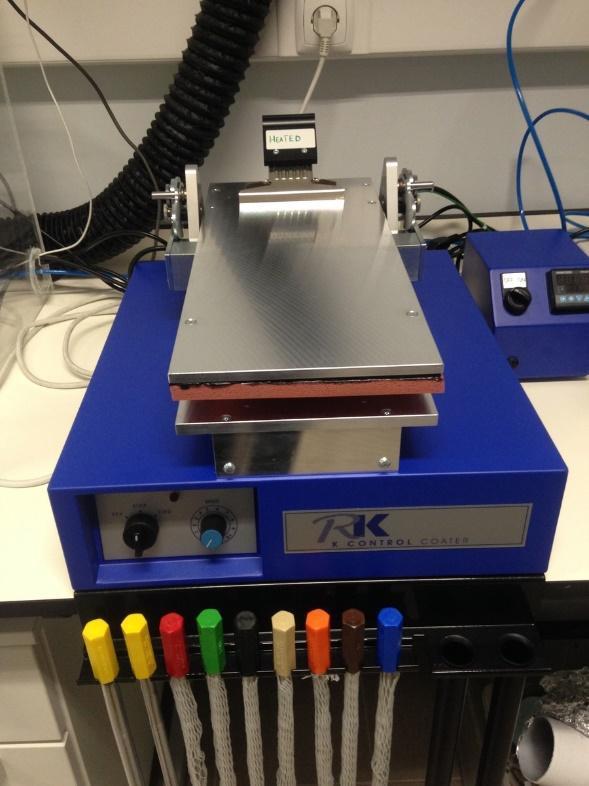

Equipment: RK Print Coat Instruments – K Control Coater model K101

Technique: Doctor blade coating

Contact person (UNINOVA): Pedro Barquinha (pmcb@fct.unl.pt), Ana Rovisco (a.rovisco@fct.unl.pt)

Responsible: João Resende (joao.resende@almascience.pt), Inês Cunha (i.cunha@campus.fct.unl.pt)

Description: The K Control Coater is widely used for the application of paints, varnishes, adhesives, liquid printing inks, among other surface coatings, to produce quick, accurate and repeatable samples. It uses gap applicators to coat onto paint test charts, steel panels and many other substrates. Meter bars provide the simplest method of applying accurate,an repeatable surface coatings.

Specifications:

-

- Controlled speed and pressure ensures repeatable results;

- Coating by wire wound bars or gap applicators;

- 2 models offer coating areas of up to 170 x 250 mm/ 325 x 250 mm;

- Multiple coatings in one operation for comparison purposes;

- Standard coating speeds variable between 2 and 15 m/min;

- K101 meter bars:

- Nº0 White/4 micron

- Nº1 Yellow/6 micron

- Nº2 Red/12 Micron

- Nº3 Green/24 Micron

- Nº4 Black/40 Micron

- Nº5 Horn/50 Micron

- Nº6 Orange/60 Micron

- Nº7 Brown/80 Micron

- Nº8 Blue/100 Micron

- Coating beds:

- Vacuum beds:

- Type A: suitable for delicate or stretchy substrates, such as aluminium foil or polythene.

- Type B: suitable for more rigid substances, and especially recommended when coating on to paint charts with gap applicators.

- Vacuum beds:

- Magnetic bed: suitable for magnetic substrates.

-

- Heated bed: suitable for coatings which require heating up to 150ºC.

- Glass bed: provides a perfectly flat surface; it is especially recommended for gap applicators which provide a hard surface.

Link for additional information: https://www.rkprint.com/products/k-control-coater/