In a significant development for the field of wearable technology and portable systems, the EMERGE project has achieved a breakthrough in the manufacturing of flexible, multifunctional sensors that respond to multiple external stimuli. This advancement holds great promise for the low-cost production of devices that will shape the future of Industry 4.0.

The research study, published in Advanced Materials Technologies, was a part of a Joint Research Activity within Emerge Project, involving the participation of Technische Universität Dresden (TUD) and Hellenic Mediterranean University. Additionally, the groundbreaking outcomes from a project submitted during the 1st open call, carried out at TUD and led by Bing Wu, a PhD student from Prof. Zdeněk Sofer’s group at the University of Chemistry and Technology, Prague, significantly contributed to the study’s success.

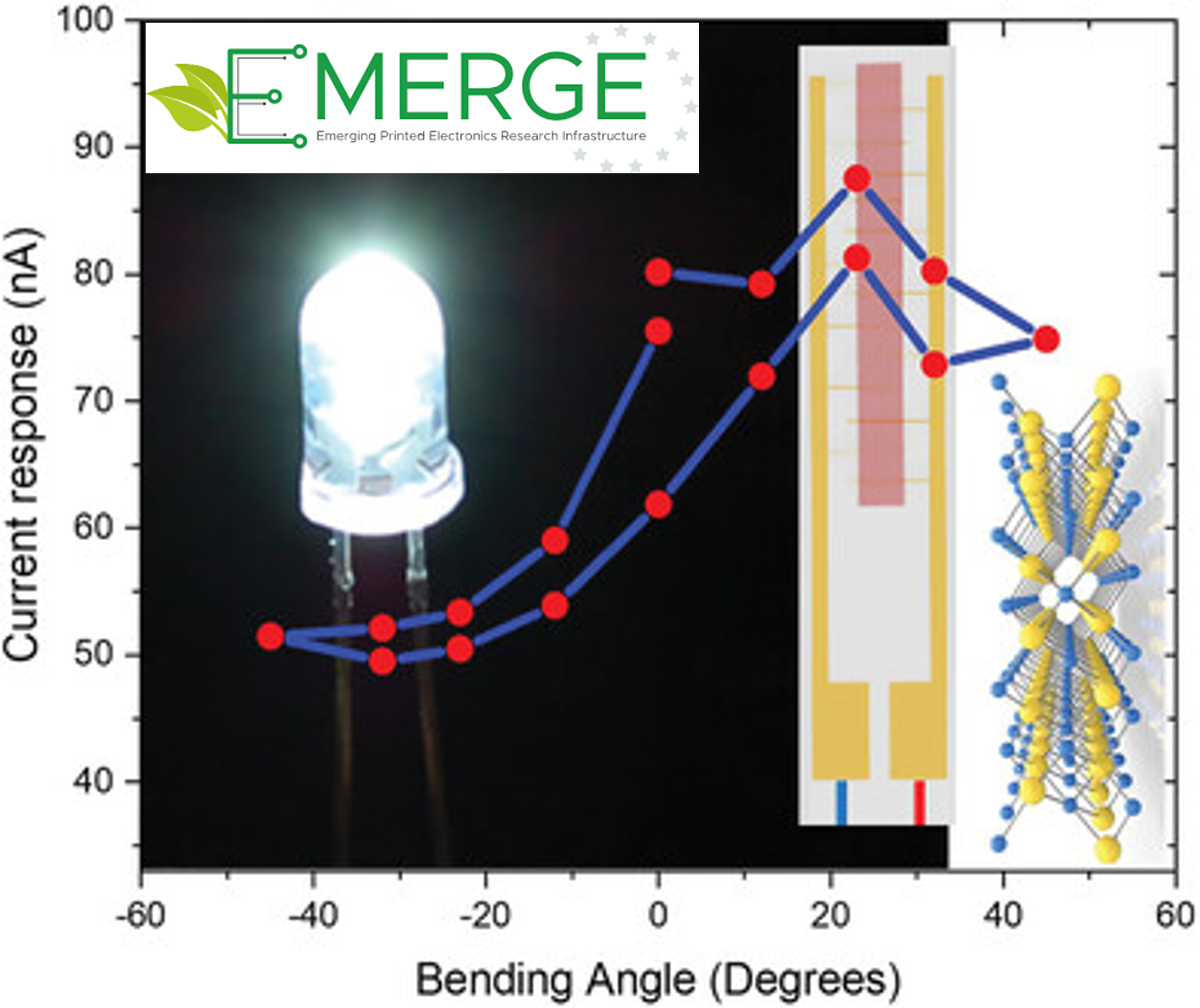

This work outlines a facile, ultralow-cost, and up-scalable printable manufacturing process that utilizes a novel spray coating system for the fabrication of multifunctional sensors on plastic foils, capable of simultaneously responding to light illumination and mechanical deformation. This achievement signifies a significant advancement in the field of flexible electronics, as it combines multiple functionalities in a single device, thereby further simplifying the manufacturing process and reducing associated costs.

The key component of these sensors is the active layer, which is based on defect-free In2Se3 nanosheets possessing inherent piezo-phototronic properties. The team successfully formed these nanosheets using an in-house spray coating system, showcasing the effectiveness of the novel manufacturing technique. By utilizing the same material stack as a multifunctional sensing element, the researchers demonstrated the efficiency of the devices as photodetectors tunable by mechanical strain and force sensors capable of responding to different levels of applied force. These force sensors consistently produce discrete piezoelectric voltages in the millivolt scale when subjected to various mass loads, holding immense potential for diversified applications such as tough displays, tactile sensing, or force detection.

The EMERGE project continues to drive progress in the field of flexible large-area electronics and photonics, bringing us closer to a future where smart, adaptable devices enhance our daily lives.