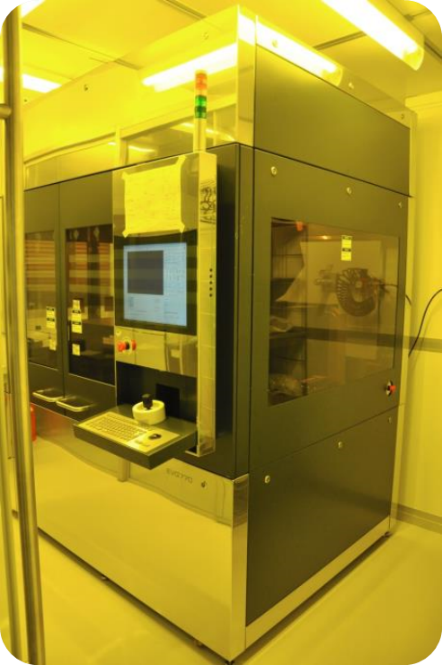

Equipment: EVG 770 customized foil stepper

Technique: Step & Repeat UV-Nanoimprinting

Contact person (Joanneum Research): Barbara Stadlober (barbara.stadlober@joanneum.at)

Responsible: Ursula Palfinger (ursula.palfinger@joanneum.at)

Description: JR´s step&repeat technology is based on an EVG 770 wafer stepper. It is used for pattern upscaling via UV imprint lithography to mainly generate flexible, polymer-type shims. Compared to the standard tool, this foil stepper has been upgraded by a large-area stage enabling to bear shim-sized (270×660 mm²) flexible and rigid substrates, a larger imprint head, additional alignment possibilities and a live camera for inspection of the filling process.

Specifications: The S&R repeat infrastructure is located in a micro-cleanroom ensuring particle control and a temperature stability of ± 1°C. It allows to successively replicate pattern fields with a very high positioning accuracy. The active area of the single die (the pattern field that is copied) can be in the range of 10×10 mm² to 50×50 mm². The positioning accuracy of the stage is about 3 µm over an area of 300×300 mm². Two basic principles for an upscaling process can be applied: a) the single fields are replicated with a defined distance to each other and featuring unpatterned gaps in between; b) seamless stitching of the single fields, where the adjacent fields are positioned precisely in contact to one another, i.e. with negligible gaps, leading to a real area upscaling.

The machine is equipped with two dispenser types, a top dispenser for droplet application of the resin onto the substrate, and a bottom dispenser, that allows the coating of the stamp. Second is seen as preferable when dealing with patterns with high cavity volume. Resin exposure can be done via a low-power broadband UV lamp or, a new alternative, via a high-power UV LED.

Link for additional information: https://www.joanneum.at/en/materials/research-areas/large-area-micro-and-nanostructuring/step-and-repeat