Equipment: Pastes/inks production line: hotplate stirrers Heidolph MR Hei Tec, ultrasonic baths Intersonic, three roll mill EXAKT 80E, IKA evaporator RV 10, laboratory scales, Kakuhunter Planetary Mixer SK-350TII CE, mortar grinder Retsch RM 200, Ultrasonic reactor VC 750 Sonics&Materials.

Technique: Preparation processes for pastes and inks for printing electronic techniques

Contact person (Warsaw University of Technology): Jakub Krzemiński (Jakub.krzeminski@pw.edu.pl)

Responsible: Sandra Lepak-Kuc (sandra.kuc@pw.edu)

Description:

Basic laboratory equipment for the pastes and inks production. Weighing, deagglomerating, homogenizing and grinding.

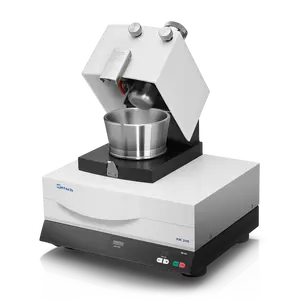

- Mortar grinder enables dry and wet grinding of soft, medium-hard, hard materials, also in the form of pastes, with a hardness of up to 9 on the Mohs scale.

- Three Roll Mill is crucially important in the research, development and production of especially nanocarbon-based materials, but also others. They enable high-precision dispersion down to the nano range as well as the homogenization and improvement of the rheology of printing pastes

Specifications:

- The balances indicate the measured result to 4 decimal places.

- Ultrasonic baths of capacities of 1,8-2,8l and 6-10l.

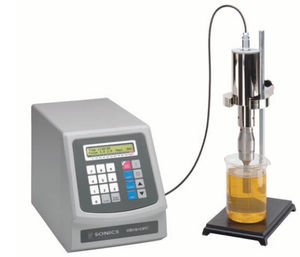

- Ultrasonic reactor: 750 Watt, from 250 microliters to 1 liter; 10 hour process timer.

- Kakuhunter Planetary Mixer SK-350TII CE: 90 different revolution-rotation speed patterns are available by varying the ratio of revolution and rotation, speed: 0 rpm – 1,430 rpm.

- Three roll mill EXAKT 80E: maximum product fineness up to < 1µm, depending on the product; output between 0.02 and 20 l per hour- IKA evaporator RV 10: Speed range 5 – 280 rpm; Reversible direction of rotation; Heating temperature range: room temperature – 180 °C.

- Hotplate stirrers: Rotation speed range 100 – 1,400 rpm; Hotplate temperature 20 – 300 °C.

- Mortar grinder: Batch quantities ~10 – 190 ml with a maximum grain size of 8 mm.